Laser-based additive manufacturing of metal parts from powder in microgravity

| Led by: | M. Sc. Marvin Raupert |

| E-Mail: | marvin.raupert@ita.uni-hannover.de |

| Year: | 2021 |

| Funding: | DFG |

| Duration: | 07.2021 - 06.2024 |

Fixed base stations are to be set up on the moon and on Mars in the near future. Accordingly, the duration and number of space missions will continue to increase in the long term. At the same time, the probability of component failures increases during the flight. In order to be able to react quickly in such a case, a process must be developed where parts can be manufactured or repaired, so that the total mass of spare parts on the spaceship can also be reduced to a minimum.

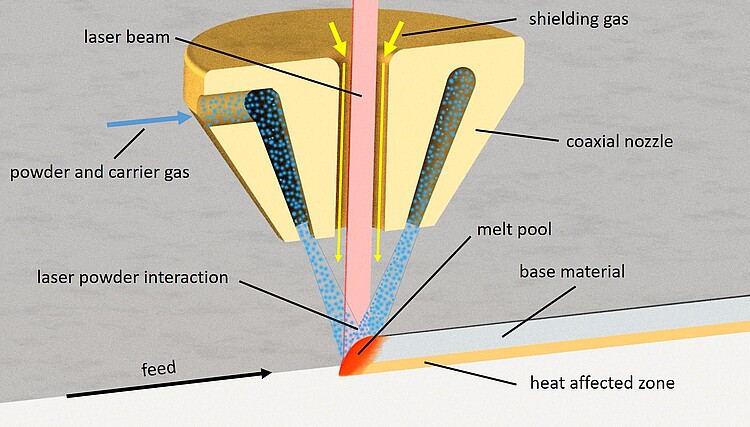

The project is implemented through the development of a laser-based additive manufacturing process for the production of metal parts from powder (titanium and nickel alloys) in microgravity in a pressurized volume. The approach is based on the "Laser Metal Deposition" (LMD) process known for earth gravity. The aims of the research project are the development of a reliable powder handling technology, an LMD device and the guarantee of a stable melting process. The production of microgravity is done with the help of the Einstein-Elevator.

The project is being carried out by the Institute of Transport and Automation Technology (ITA) at Leibniz University Hannover in cooperation with the Institute für Logistics and Material Handling Systems (ILM) at Otto-von-Guericke University in Magdeburg.

Funding by: DFG - Deutsche Forschungsgemeinschaft

| Project title: Laser-based additive manufacturing of metal parts from powder in microgravity | |

|---|---|

| Acronym | LMD in µg |

| other participating institutes/partners | Institute of Logistics and Material Handling Systems (ILM) Otto-von-Guericke University Magdeburg |

| Project Manager | Prof. Dr.-Ing. Ludger Overmeyer |

| other participating researchers | Dr.-Ing. Christoph Lotz |